News

-

Common Problems in the Welding Process! Welder Must Collect

Common problems in the welding process! Welder must collect Welding defects can be divided into internal defects and external defects according to their position in the weld. External defects are located on the outer surface of the weld and can be seen directly. External defects mainly include we...Read more -

How to Solve These Problems of Carbon Dioxide Gas Shielded Welding

How to solve these problems of carbon dioxide gas shielded welding Introduction: In CO2 gas shielded welding, poor wire feeding and uneven wire output often occur during welding, which will bring difficulties to welding and directly affect welding quality. The weld that should be welded at a tim...Read more -

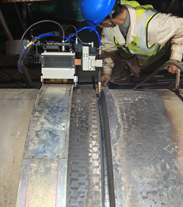

Pipeline All-position Automatic Welding Machine (Magnetic Suction Type)

Pipeline All-position Automatic Welding Machine (Magnetic Suction Type) Product model: HW-ZD-201 Applicable pipe diameter: ≥DN1168 Performance characteristics: 1. The all-position automatic welding machine is suitable for long-distance pipelines or fixed welding seam filling and cap welding at i...Read more -

Welding Basic Knowledge Collection

Welding Basic Knowledge Collection 1. What is welding? Answer: Two or more materials (same or different) are heated or pressurized or both are used to achieve the bonding between atoms to form a permanent connection. The process is called welding. 2. What is an arc? Answer: It is supplied by the...Read more -

Welding Industry Common Knowledge

Welding Industry Common Knowledge Welding Classification: ⑴ Fusion welding SMAW:Shielded metal arc welding SAW:Submerged arc welding TIG:Tungsten Inert-Gas arc welding MIG:metal Inert-gas arc welding ⑵ Pressure welding Cold welding Friction welding Diffusion welding Explosive welding ⑶ So...Read more -

Comparison of Four Non-destructive Testing Methods

Comparison of Four Non-destructive Testing Methods Non-destructive testing is to use the characteristics of sound, light, magnetism and electricity to detect whether there are defects or inhomogeneities in the inspected object without damaging or affecting the performance of the inspected object...Read more -

The Real Cause of Contact Tip Wear and Improvement Measures

Frequent replacement of the contact tip: The appearance is that the outlet of the contact tip is worn out, causing wire feed deflection... In fact, the welding track is offset, that is, the position of the TCP point is shifted, resulting in welding defects such as weldin...Read more -

Causes of Unstable Wire Feeding in FCAW/GMAW

In recent years, welding technology has developed rapidly, and various new welding equipment and new processes have been widely used in various industrial fields. Because of its high production efficiency, CO2 gas shielded welding uses a much higher current density than manual welding and submer...Read more -

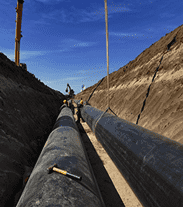

Automatic Welding of Oilfield Pipelines

Traditional welding technology and equipment and technology can no longer meet the requirements of construction quality and efficiency. In-ground engineering construction, pipeline welding quality, and welding efficiency directly affect the pipeline's life cycle and con...Read more -

YX-G168 Single Torch Orbital Pipeline Welding Machine

YX-G168 single torch orbital pipeline automatic welding machine is a new type of automatic welding equipment that combines a new generation of control technology and welding process technology. It is mainly used for filling welding and cap welding of long-distance pipel...Read more -

What is Welding Procedure Qualification

Welding Procedure Qualification (Welding Procedure Qualification, referred to as WPQ) is the test process and result evaluation for verifying the correctness of the proposed weldment welding procedure. Welding procedure qualification is an important measure to ensure ...Read more -

Application Fields of Automatic Welding

Application Fields of Automatic Welding With the development of the economy, people are increasingly dependent on energy demand. Pipeline transportation is an important means of energy transportation. It is safe and economical and therefore has been widely used. T...Read more